Описание слайда:

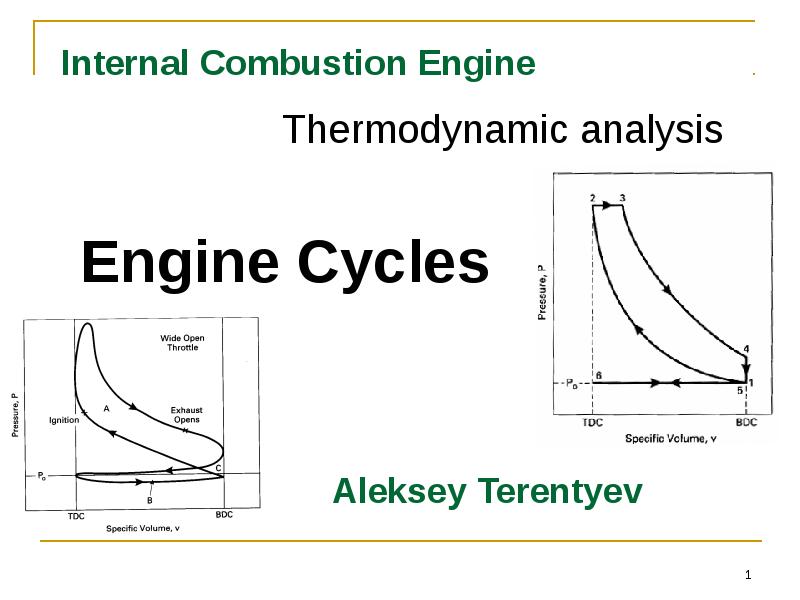

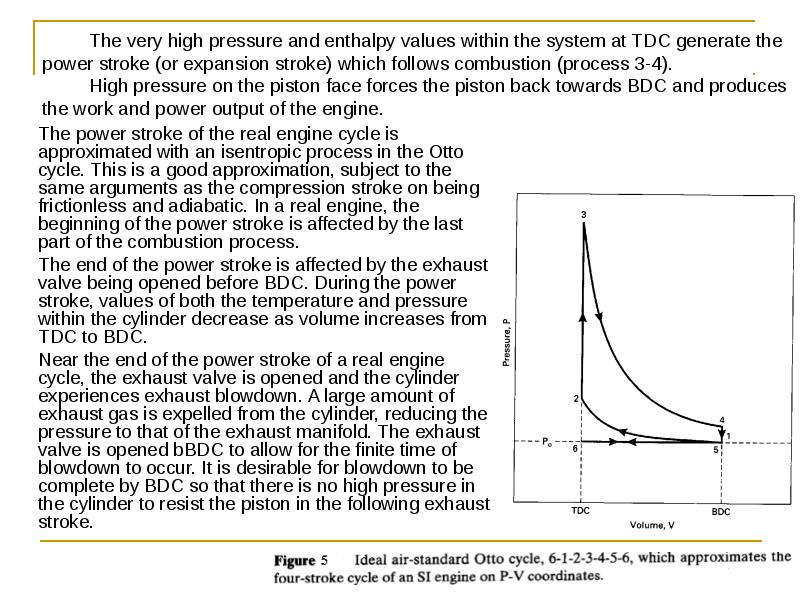

4. Combustion requires a short but finite time to occur, and heat addition is not instantaneous at TDC, as approximated in an Otto cycle. A fast but finite flame speed is desirable in an engine. This results in a finite rate of pressure rise in the cylinders, a steady force increase on the piston face, and a smooth engine cycle. A supersonic detonation would give almost instantaneous heat addition to a cycle, but would result in a.rough cycle and quick engine destruction. Because of the finite time required, combustion is started before TDC and ends after TDC, not at constant volume as in air-standard analysis. By starting combustion bTDC, cylinder pressure increases late in the compression stroke, requiring greater negative work in that stroke. Because combustion is not completed until aTDC, some power is lost at the start of the expansion stroke (see Fig. 1). Another loss in the combustion process of an actual engine occurs because combustion efficiency is less than 100%. This happens because of less than perfect mixing, local variations in temperature and air-fuel due to turbulence, flame quenching, etc. SI engines will generally have a combustion efficiency of about 95%, while CI engines are generally about 98% efficient.

4. Combustion requires a short but finite time to occur, and heat addition is not instantaneous at TDC, as approximated in an Otto cycle. A fast but finite flame speed is desirable in an engine. This results in a finite rate of pressure rise in the cylinders, a steady force increase on the piston face, and a smooth engine cycle. A supersonic detonation would give almost instantaneous heat addition to a cycle, but would result in a.rough cycle and quick engine destruction. Because of the finite time required, combustion is started before TDC and ends after TDC, not at constant volume as in air-standard analysis. By starting combustion bTDC, cylinder pressure increases late in the compression stroke, requiring greater negative work in that stroke. Because combustion is not completed until aTDC, some power is lost at the start of the expansion stroke (see Fig. 1). Another loss in the combustion process of an actual engine occurs because combustion efficiency is less than 100%. This happens because of less than perfect mixing, local variations in temperature and air-fuel due to turbulence, flame quenching, etc. SI engines will generally have a combustion efficiency of about 95%, while CI engines are generally about 98% efficient.

5. The blowdown process requires a finite real time and a finite cycle time, and does not occur at constant volume as in air-standard analysis. For this reason, the exhaust valve must open 40° to 60° bBDC, and output work at the latter end of expansion is lost.

6. In an actual engine, the intake valve is not closed until after bottom-dead center at the end of the intake stroke. Because of the flow restriction of the valve, air is still entering the cylinder at BDC, and volumetric efficiency would be lower if the valve closed here. Because of this, however, actual compression does not start at BDC but only after the inlet valve closes. With ignition then occurring before top dead-center, temperature and pressure rise before combustion is less than predicted by air-standard analysis.